频闪仪用于工业设备的维护检查

频闪仪用于印刷行业的速度和质量测量

频闪的使用允许您在具有重复加工周期的机器上对生产过程进行缓慢的观察。在配备同步光电池或来自机器PLC的信号的机器上,可以快速、立即地将闪光灯与生产过程同步,并准确地看到产品,就像它在印刷、模切或包装过程中直接停止一样。除了观察减速运动外,频闪仪还允许您进行测量并计算机器每分钟的行程数。此函数对于确定工厂的生产率或计算机器的小时产量特别有用。

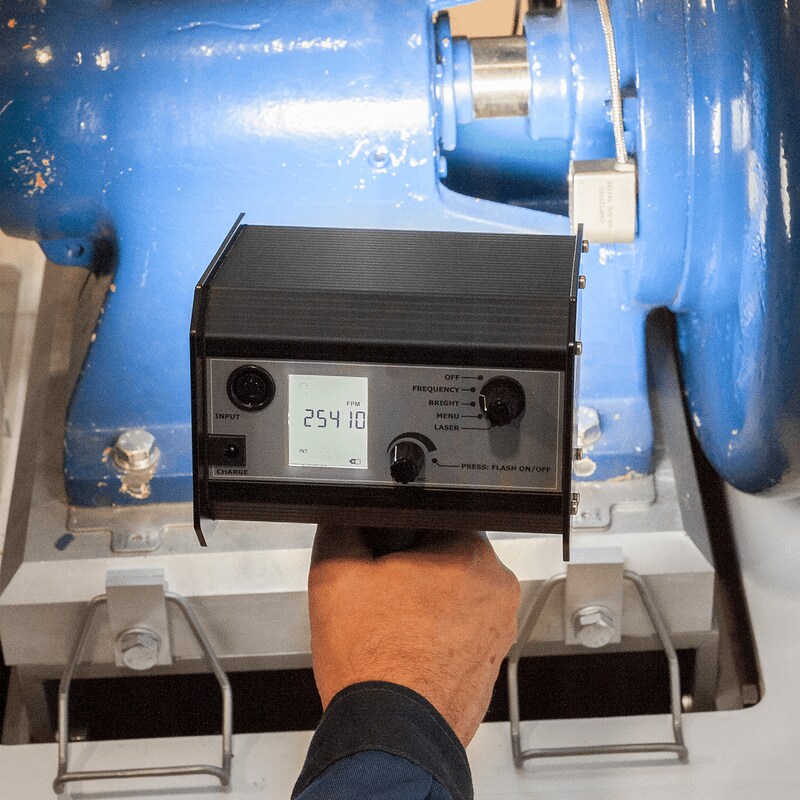

频闪仪用于设备预防性维护和正确的机械装配检查

并非总是能够观察到运动机械部件的行为,以验证其正确组装或是否存在因不规则磨损而导致的异常振动。使用闪光灯可以冻结齿轮、杠杆、阀门或任何以每秒高次数重复运动的机构的运动。通过频闪仪闪光与被观察物体的运动同步来减缓运动,可以减缓对物体的观察,识别可能影响物体可靠性的任何运动缺陷、形状或尺寸缺陷。”应用程序。

频闪仪用于纺织和造纸行业的印刷控制和正确设置

笔划允许您冻结具有重复运动或规则打印的连续对象或磁带的运动。通过这种方式,很容易看出商标、徽标或文本是否正确打印,没有污迹,颜色和字体参考是否正确。。典型的应用还包括在打印后立即在生产线上直接观察打印质量,而无需等待打印卷筒或色带停止并在稍后阶段进行分析。直接在生产线上检查印刷品的可能性使您能够立即发现问题,避免生产出浪费的材料。

Speed and quality measurement in the printing industry.

The use of strobes allows you to carry out slowed observation of the process of production on machines that have repetitive processing cycles. On machines equipped with synchronization photocells, or with the signal coming from the machine PLC, it is possible to perform one fast and immediate synchronization of the strobe with the production process and see the product exactly as if it were stopped directly during printing, die-cutting or during packaging. In addition to the observation of slowed down movement, the stroboscopes allow you to take measurements and count the number of strokes per minute of the machine. This function is particularly useful for determining the productivity of a plant or for calculating the hourly production of a machine.

Preventive maintenance and correct mechanical assembly check

It is not always possible to observe the behavior of moving mechanical parts to verify their correct assembly or the presence of abnormal vibrations due to irregular wear. The use of strobes allows you to freeze the movement of gears, levers, valves or any mechanism that works with repetitive motion at a high number of times per second. The slowing of the movement, carried out through the synchronization of the stroboscope flash, with the movement of the object under observation, allows the slowed observation of the object, identifying any movement defects, shape or size defects that could compromise the reliability of the object. 'application.

Control of printing and correct setting in the textile and paper sector

Strobes allow you to freeze the motion of a continuous object or tape that has repetitive motion or regular printing. In this way it is easy to see if a trademark, logo or text is printed correctly, without smudging, with the correct color and font references.. Typical applications also include observing print quality directly on the production line, immediately after printing, without waiting for the printed reel or ribbon to be stopped and analyzed at a later stage. The possibility of inspecting the print directly on the production line allows you to identify the problem immediately, avoiding the production of material that would otherwise be waste.

Stroboscopes - Introduction to choice

There are many stroboscopes on the market with very different characteristics and prices.

In this section we collect some tips that we believe may be invaluable in selecting the correct tool.

Intensity and quality of light

Much of the cost of the stroboscope is determined by the quality of the lamp used and the amount of light it is capable of emitting.

Stroboscopes must be able to emit flashes of light with an extremely short pulse duration, in the order of a few microseconds (some drop below 10 microseconds), otherwise the strobing effect is not visible or the quality of the display of the object is poor.

Not only must the lamp emit fast and very bright pulses of light but it must also be able to last for several million cycles because the stroboscopic effect is often observed at very high frequencies.

Therefore all the goodness of the stroboscope is played on the quality of the lighting system.

Often medium-low end stroboscopes characterized by very competitive costs employ lamps whose duration is limited in time and the light emitted is of insufficient intensity to observe the object.

Furthermore, some stroboscopes do not allow to change the lamp compromising the use of the entire instrument when the lamp has exhausted its life. Always pay attention to the possibility for a stroboscope to be able to change the lamp (unless it is an LED stroboscope and therefore maintenance-free).

Another problem that must always be kept in mind is the presence of ambient light. In fact, it is not always possible to work in a completely dark environment and the light emitted by the stroboscope must always contrast the light of the surrounding environment.

Very often inexpensive stroboscopes are tested in completely dark environments and when working in the field the desired effect is not obtained.

路阳频闪仪:电动牙刷、乐器、音响行业往复运动研究的得力助手

路阳频闪仪:电动牙刷、乐器、音响行业往复运动研究的得力助手

选择检测频闪仪时要考虑的 11 个因素

选择检测频闪仪时要考虑的 11 个因素

LED 频闪灯如何提高钢厂生产效率

LED 频闪灯如何提高钢厂生产效率

LED频闪仪主要有哪些应用

LED频闪仪主要有哪些应用